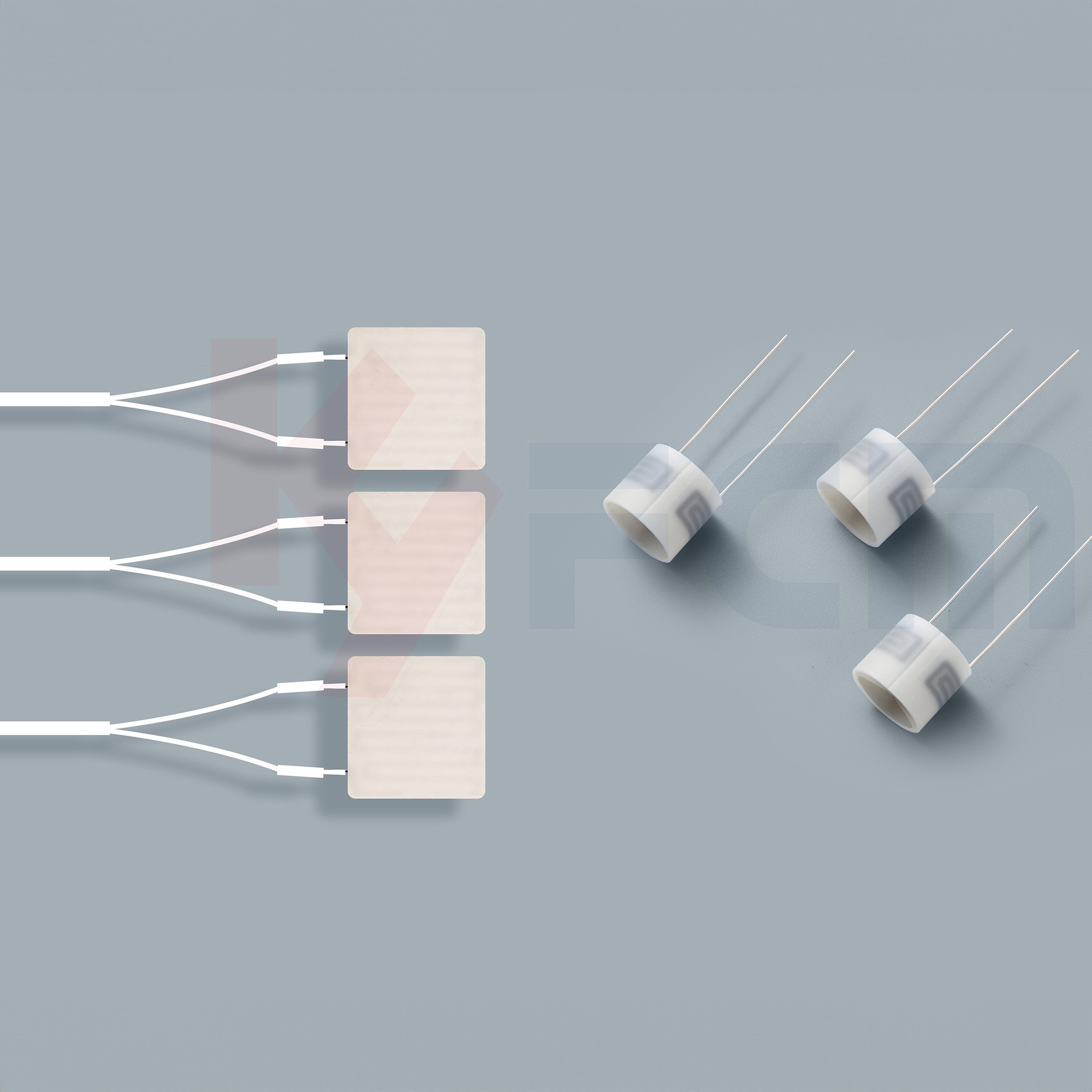

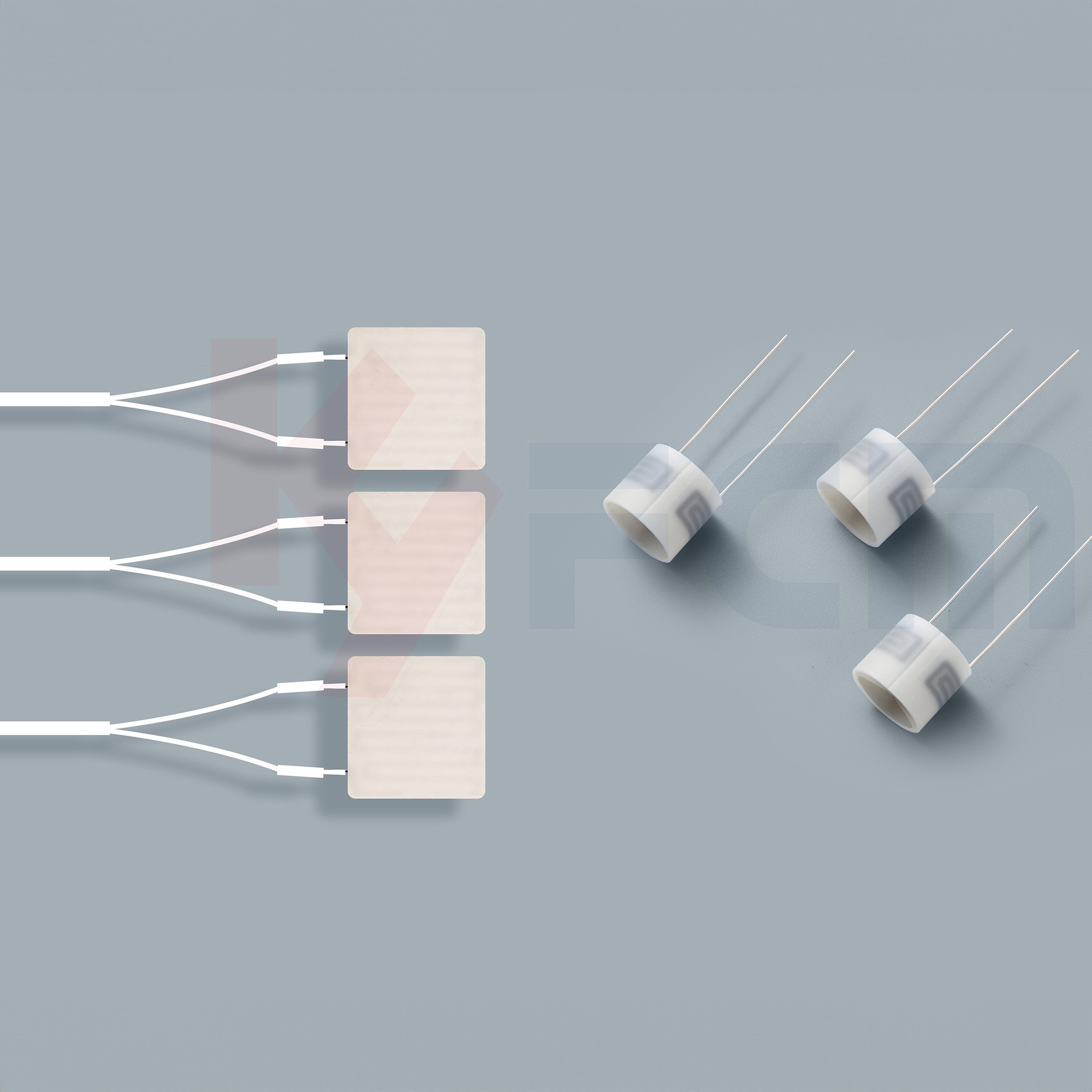

Aluminum nitride is a multifunctional material, most commonly used in scenarios that require high thermal conductivity and electrical insulation. This unique ability makes AIN an ideal choice for fast heating and heat dissipation. Such as aluminum nitride ceramic heaters, aluminum nitride ceramic wafer trays / ceramic chucks, etc.

Product Introduction

Material Parameters

Performance Parameters