The upgrade and iteration of semiconductor equipment depends largely on the key technological breakthroughs of precision parts. Among them, Electrostatic chuck is a typical segmented parts market, which plays an important role in many links of semiconductor manufacturing process. There are hundreds of process steps in the advanced large-scale integrated circuit manufacturing process, and the wafer needs to be transferred back and forth between hundreds of process equipment and processed and tested. During the processing, the wafer must be placed on the process equipment very stably and fixedly. At present, the global Electrostatic chuck market is mainly dominated by Japanese and American companies. As a core component with a relatively high value share in semiconductor manufacturing process equipment, Electrostatic chuck currently has a large space for domestic substitution.

What is Electrostatic chuck

Electrostatic Chuck (ESC), also known as electrostatic suction cup, is a superior technology that uses electrostatic adsorption to replace traditional mechanical clamping and vacuum adsorption. It is called "the invisible hand that fixes the wafer in the semiconductor process" and plays an important role in the processing process. It is currently mainly used in ion etching ETCH, ion implantation IMP, physical vapor deposition PVD, and chemical vapor deposition CVD.

Classification of Electrostatic Chuck

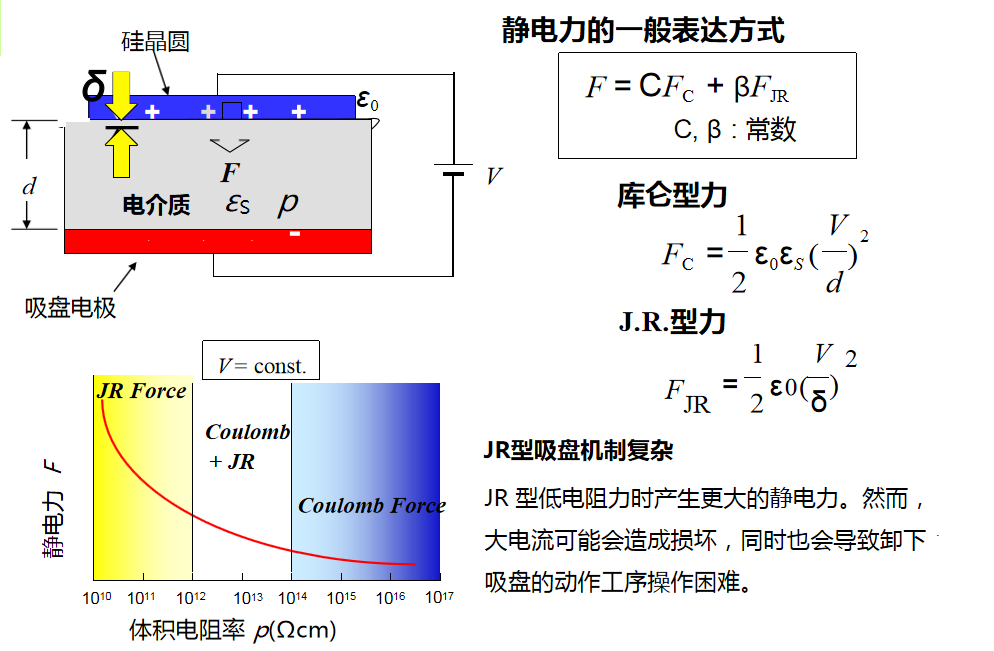

Electrostatic chucks (ESC) can be divided into two types: Coulomb type and J-R type. The difference between the two is that when high voltage DC is applied to the electrostatic chuck, the upper surface of the ceramic dielectric layer of the Coulomb type electrostatic chuck will generate polarized charges with opposite polarity to the adsorbed product, thereby forming an electrostatic attraction to achieve adsorption and fixation. In the J-R type electrostatic chuck, the charged ions in the ceramic dielectric layer migrate and gather on the upper surface, forming a strong electric field between the electrostatic chuck and the adsorbed product, thereby achieving adsorption and fixation.

Domestic manufacturers of electrostatic chucks——广Fine Ceramic New Material Co.,Ltd.

Fine Ceramic New Material Co.,Ltd.With many years of experience in HTCC R&D and production, it focuses on the R&D and manufacturing of ceramic Electrostatic chuck (ESC) for semiconductors, precision ceramic vacuum suction cups, and aluminum nitride ceramic heating elements. It has established a test center with ESC special test equipment, SEM, three-coordinate, profilometer and other test equipment, and has the R&D and production capabilities of Coulomb type and J-R type electrostatic chuck ESC made of alumina and aluminum nitride. At the same time, Guangdong Jingci has also effectively solved the pain points of powder loss, particle loss and uneven adsorption force in the industry on ceramic vacuum suction cups, and can provide a safe supply of key components for semiconductor equipment and semiconductor chip manufacturing.

Fine Ceramic New Material Co.,Ltd.Main Products

Fine Ceramic New Material Co.,Ltd.It has an annual production capacity of 2,000 sets of 8-inch and 12-inch aluminum oxide & aluminum nitride electrostatic chucks and 20,000 sets of silicon carbide & aluminum oxide vacuum chucks with a size of more than 300 mm. Its main products are as follows:

1.Electrostaticchuck(ESC)

(1) Coulomb type electrostatic chuck

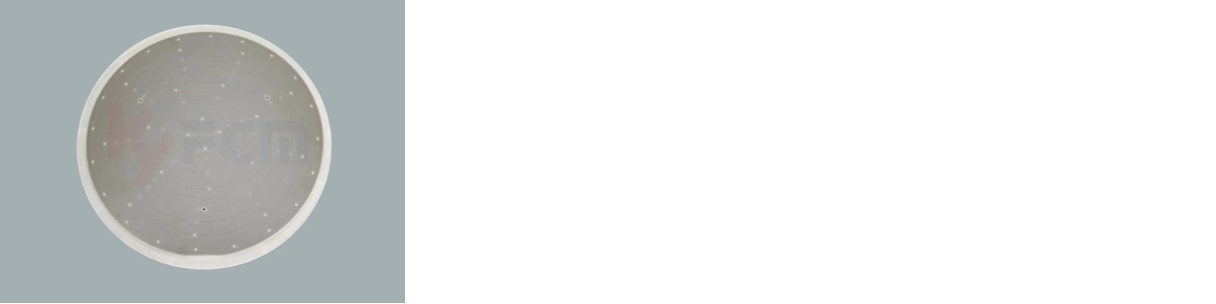

▲ 12 inch alumina electrostatic chuck

▲ 12 inch alumina electrostatic chuck

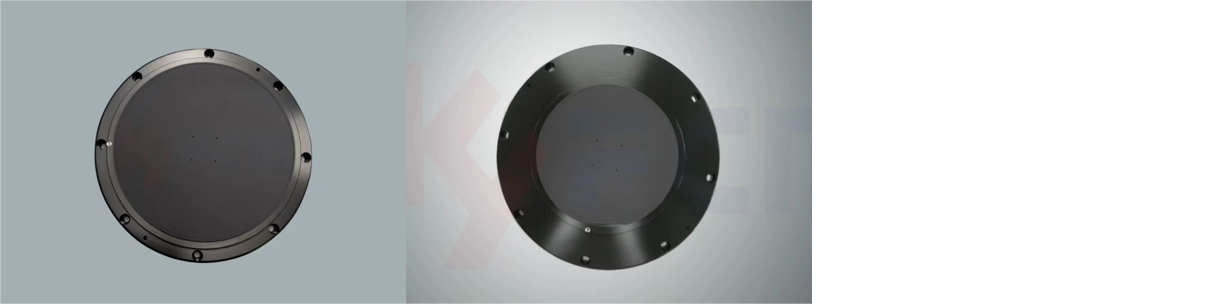

(2)J-R type electrostatic chuck

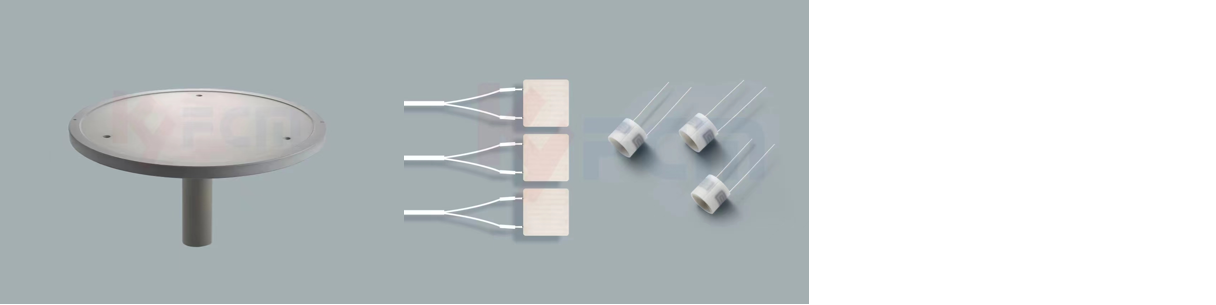

2、Ceramic Vacuum Chuck

3、AlN Ceramic Heater

If you want to know more or contact us (email: asstfcm@kymch.com), Guangdong Fine Ceramics will contact you as soon as possible.